SAP connections

We create connections:

For uniform, central control of all processes important to the company!

We are your innovative solution provider:

Communication between ERP systems and production is possible!

Do you still know the song of the Fantastischen Vier "with friendly greetings"?

"ARD, ZDF and C and A ..." - This is how it sounds when it comes to the world of ERP systems: DMS, BDE, xRM, MES ... it is not easy to maintain an overview here and to understand what it is all about. It is even more difficult to create a link between the often inhomogeneous systems and thus achieve uniform control of all your production processes and the administration running in the background.

But not for us!

We ensure that your ERP system, where the digital threads come together, is seamlessly connected to all technologies.

of your system landscape is connected. And thus enable central control and smooth communication

of all your business-critical processes!

Of course, we don't limit ourselves to connecting the digital infrastructure -

a connection of your machinery is of course also possible.

All our solutions are thereby ...

✔ individually adapted to you and your system landscape

✔ Modular and constantly expandable according to your growing requirements

✔ elaborated with you in comprehensive workshops

✔ Exclusively created by us specifically for you and your requirements - no "off-the-shelf" products that still need to be optimized

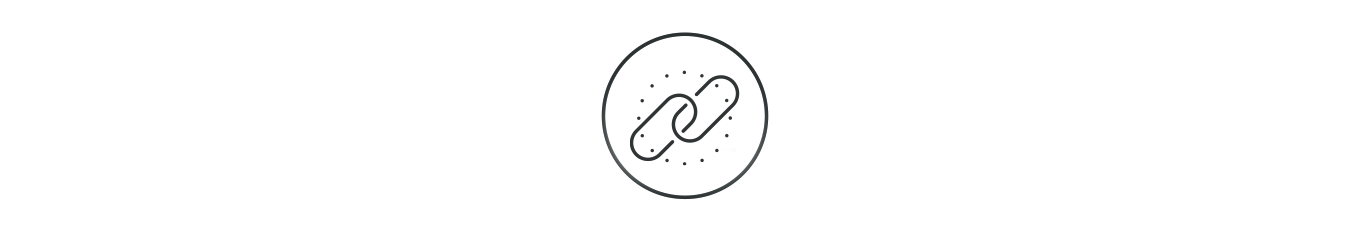

Live example

The tangible solution - a real example of our work

Machines. Production machinery. Real, analog, heavy equipment that produces and processes cardboard packaging in the machinery of a medium-sized company. Or better: should process! Because: Data is also processed in these machines - and after the company introduced SAP, they are at a standstill. A disaster for any business.Thanks to us, the machines are now running again - read for yourself:

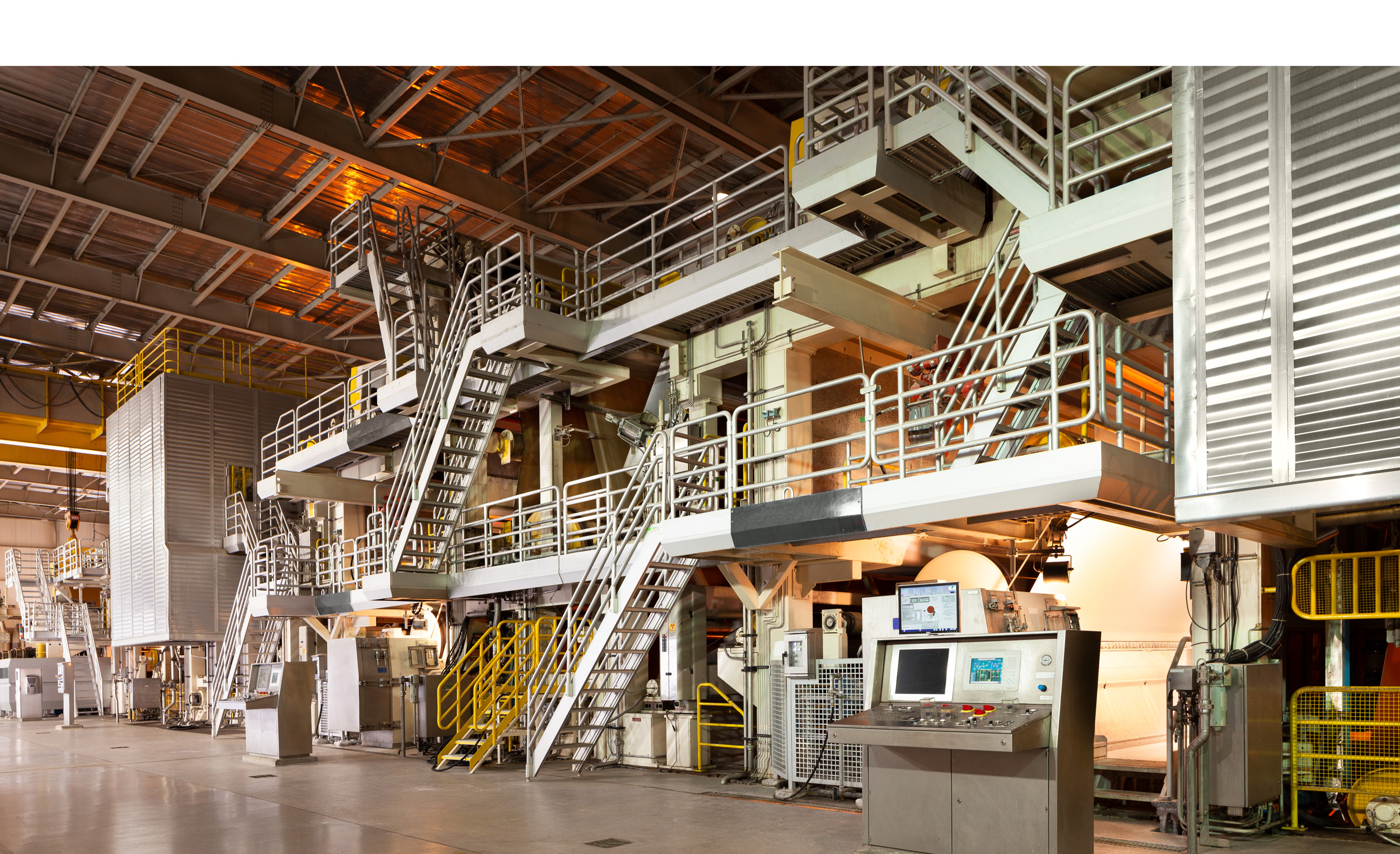

Our solution: Transfer of data from SAP - at the push of a button!

In our example, the company previously had a homegrown ERP system in use, with deep machine connectivity built in. The workflow called for skilled workers to manually configure the machines with run sheets according to these specifications. A method with a high potential for error - and a problem in times of a shortage of skilled workers.

After the introduction of the new, SAP-based ERP system, the entire workflow had to be completely reconnected. Since we are always on the side of our customers, we have developed a solution that not only includes the connection of the machine park to the new ERP system - but also revolutionizes the entire process! The challenge: We wanted a solution that would automatically feed the information directly from SAP to the machines. This minimizes the potential for errors, and the workers at the machines no longer have to be skilled workers!

... and it runs: SIEMENS SPS <–> SAP

So we developed a middleware that enables communication between the machine controller, in this case SIEMENS PLC, and SAP. And to an extent that allows the user / operator of the machine from now on to simply select the work orders on the screen of the machine - without any further configuration being necessary.

The corresponding employee only needs to load the machine with the required materials, which can also be read from the SAP information, press the start button - and it runs!

Warehouse logistics, shipping and much more

The above example is, of course, just one of many ways in which our middleware enables communication between SAP and other processes. Another of many possibilities would be, for example, also the control of your warehouse logistics and the dispatch of goods from your warehouse - fully automated! This involves outputting information from SAP directly to employees' tablets. Our middleware thus creates communication between the machine control and the user interfaces - each prepared for the appropriate device.